Are you an actor of the leather industry?

If so, the new European Union deforestation-free regulation is impacting you.

Here is why, and most importantly, how to get prepared!

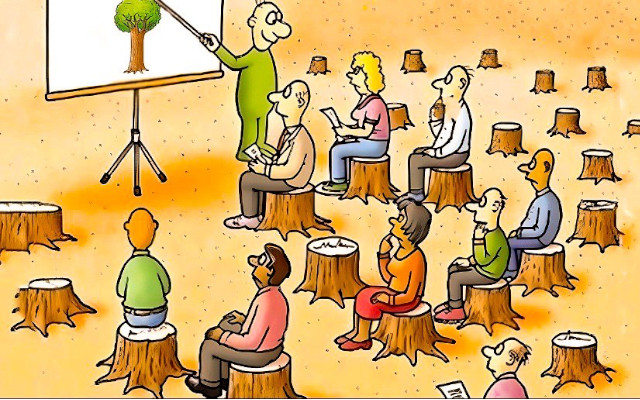

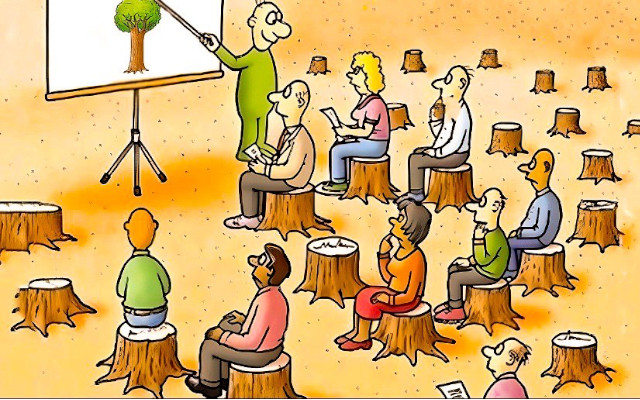

To fight deforestation caused by the import of certain products, the European Union adopted the EUDR (European Union Deforestation Regulation) in June 2023.

Inspired by the EU Timber Regulation (EUTR), in force since 2013, the EUDR will bring about a change of scale by moving from the fight against illegal timber to the eradication of deforestation and forest degradation linked to the production of raw materials.

It will apply to most companies operating within the EU from the 30th of December 2024, and will effectively prohibit European companies from importing illegal products or products linked to deforestation onto the European market.

Here are some answers!

So, you have less than a year to comply with the regulation! What is the EUDR and what impact will it have on the leather industry?

Here are some answers!

Why is this regulation so important?

The state of deforestation has been widely documented in numerous articles and reports.

However, we feel it is important to reiterate two ideas.

- The first is that deforestation continues today. Net losses of 5 million hectares per year are recorded, with significant impacts on greenhouse gas emissions, biodiversity, and local communities.

- Secondly, the EU imports account for 16% of global deforestation . We therefore have a significant responsibility to act.

Am I impacted?

The regulation covers 7 raw materials (known as “relevant commodities”), including beef, and the products derived from them, in particular leather (known as “relevant products”, listed in Annex 1 of the regulation, according to their customs code).

All steps in the supply chain are covered.

- If you import raw, semi-finished or finished leather into Europe for processing, for example as a collector, hides and skins or leather trader, tanner, you are directly concerned as a first importer on the market (under the “operator” category).

- On the other hand, if you buy leather that has already been imported onto the internal market of the European Union, in order to process it and/or resell it, you are also concerned, but under the “trader” category. The applicable requirements differ slightly (see the section entitled “Key points to remember”).

- However, if you are a brand of footwear, leather goods and accessories that produces, buys or retails finished products containing leather (which you have not reprocessed), you are not directly concerned. However, your entire supply chain will be affected, and this is likely to disrupt your sourcing of materials.

It should also be noted that while the regulation primarily targets imported deforestation, it also applies to all exports from the European Union. The same rules therefore apply if you sell leather produced in Europe on the non-European market.

Note: bear in mind that an update is due to take place within the next two years, and that other products or other actors could be included in the scope of the regulation.

What shall I prove?

To place goods on the European market (or export them), companies directly affected by the regulation (i.e. the operators) will have to meet (and prove) the following conditions:

- “Zero deforestation”: the product or raw material has not contributed to deforestation or forest degradation after 31 December 2020 (cut-off date).

- “Legal”: they have been produced in accordance with the legislation in force in the country of production (i.e. in terms of land use, environmental protection, forest management and biodiversity conservation, but also human rights, etc.).

- “Due diligence statement”: they are accompanied by a due diligence statement, produced in accordance with the requirements set out in the regulation.

In practical terms, goods will therefore be authorized to access the European market provided they are accompanied by their due diligence statement (issued by the company), whose information, well defined and specified by the regulation, will make it possible to characterize the conditions of production and thus assess the level of risk.

The main challenge facing companies is therefore the implementation of this “due diligence system“, which they will have to review at least once a year.

What penalties do I risk?

The potential fines for non-compliance are heavy: up to 4% of the importer’s EU turnover, plus confiscation of the products by customs and other authorities.

The frequency of checks will vary according to the level of risk in the production area (the EU will shortly outline a system for classifying countries according to their deforestation risk).

Key points to keep in mind

• The central concept of due diligence

The key requirement of the regulation is that operators must implement a due diligence system.

This is a 3-stage process.

>> 1. information REQUIREMENTs

Companies must collect information on their products, including a description of the product, information on the quantity, the country of production, the geolocation of the farm(s) or forest from which the product originates, the date or period of production and the name and contact details of the supplier.

Companies must also obtain conclusive proof that the production of the product is free from deforestation and complies with the laws of the country of origin.

>> 2. risK ASSESSMENT

Based on the information collected, the company must assess whether there is a risk that the products intended to be placed on the market are not compliant. The risk assessment must consider the risk level assigned to the country of production (soon defined by the European Union), as well as the presence of forests close to the production area, the presence of indigenous populations, cases of human rights violations, concerns about corruption, the complexity of the chain, etc.

This complete analysis must be documented and updated at least once a year.

>> 3. risK MITIGATION

If the risk assessment concludes that there is no (or only negligible) risk, no further action is required, and the products can be placed on the market/exported. On the other hand, if risks are identified, the company must take risk mitigation measures such as collecting additional data, carrying out audits, etc.

Note: the text provides for two levels of obligation depending on whether you are an operator or a trader. Operators are responsible for implementing the due diligence system and proving the compliance of their products, while traders are required to collect the associated due diligence statements and forward them to downstream actors.

• The requirement of traceability via geolocation of all plots of land

Traceability is at the heart of the EUDR.

As part of the data collection required by the due diligence system, the regulation requires operators to trace their supply chain back to the exact production plots of land.

The concept of geolocation refers to the GPS coordinates of the production plot, or the perimeter of the plot (using a polygon).

Please note that for cattle and leather, this geolocation requirement applies to all the establishments through which the animal has passed (e.g. farm of birth, fattening farm, etc.).

Note: associated with the use of satellite imagery data (public or private – depending on the companies’ resources), this geolocation information will be a decisive element in proving the absence of deforestation on the parcels concerned.

• Certification, an incomplete solution

The regulation clearly states that certification schemes are not a complete and sufficient response, and do not replace the corporate responsibility. They may, however, be referred to in the risk assessment to provide additional information on compliance with the requirements.

For example, the LWG standard is currently being revised to include more criteria on traceability and due diligence system.

Actors of the leather industry: major challenges to be expected

• Complex supply chains to understand

The supply chains of the commodities targeted by this new regulation are in most cases highly complex, because globalized, operated by multiple players and often opaque.

In the case of the beef industry, the traceability systems in place – where they exist – are generally designed to track meat carcasses, to meet the requirements of the agri-food industry. The traceability of derived and processed products, such as leather, is therefore often lost at slaughterhouse level, making it virtually impossible for the last players in the chain using the hides and skins to trace them back to the various places where the animals were born and reared.

Note: although batch traceability systems sometimes exist for hides and skins at slaughterhouses or tanneries, they are often not precise enough and do not necessarily meet the requirements of this regulation. Another challenge, specific to beef products and that complicates the exercise is the length of time over which they are produced. Several years pass between the birth of the animals and the processing of the hides. Animals slaughtered in 2025, and whose hides marketed within (or outside) the EU will be fully subject to the regulation, are therefore already born and possibly in the process of being moved from one fattening site to another.

• Compliance with the legislation of the country of production, a tricky requirement to assess

One of the key points of the regulation is proof that the goods have been produced in accordance with the relevant legislation in force in the country of production, for example in terms of forest management, biodiversity conservation or human rights.

But this notion of compliance by country is not so easy to assess. Beyond the variability from one country to another, understanding what is legal and what is not, and consequently ensuring that the production complies with the regulation requirements, may well prove tricky.

• LAck of available resources.

In most of the targeted sectors, the resources and tools currently in place to collect information and/or ensure traceability are inadequate to meet the regulation requirements.

For the entities concerned (and particularly the smaller ones), compliance will therefore require significant adjustments in terms of internal organisation, logistics and production costs, which will undoubtedly require considerable human, technical and financial investment.

• Market and supply disruption

At market level, supply chains are likely to be disrupted and raw hides and skins purchases might become more complex.

In addition to the expected increase and volatility in costs caused by the additional charges mentioned above, possible supply difficulties, or even stock-outs, could arise for products from supply chains verified as compliant and traceable.

To conclude… it is time to act!

“Transparency and traceability are close to non-existent in leather supply chains, and it is highly likely that companies buying leather from the major Brazilian leather suppliers buy leather from cows that have grazed on deforested land. Currently, no one can prove that the leather they buy is deforestation-free.”

Anne Leifsdatter Grønlund

As underlined by Anne Leifsdatter Grønlund, zero deforestation advisor at Rainforest Foundation Norway, this regulation is as ambitious as it is necessary.

Wherever you act in the supply chain, control over your purchases, traceability and due diligence are key concepts to implement, right now.

Thanks to our expertise in the leather industry and responsible sourcing, we can help you meet these challenges!

Here are a few essentials:

- Start by mapping your supply chains (traders, beamhouse or finishing tanneries, etc), then commit to a product traceability process.

- Engage with your suppliers: they are key operational actors, without whom you won’t be able to achieve your objectives.

- Get closer to your sources (the farmers)! In this way, you can build perfectly controlled supply chains.

Need to go deeper?

Let’s talk together!

- Emilie Floc’h – Co-founder of Origem

emilie.floch@origem.fr - Audrey Laffaille – Sustainable sourcing project manager

audrey.laffaille@origem.fr